The food is an aspect of great economic importance in the creation of commercial poultry not only because it is primarily responsible for the growth response of the birds, it allows the birds to express their genetic potential, but mainly because it represents the largest cost in the production cycle.

In creating chicken cut feed conversion rate (CA) is a performance indicator management and also profit at a given cost of feed. As these costs represent 60-70% of the total cost of broiler production, the efficient conversion of feed into body weight is essential to profitability, and small changes in feed conversion rate regardless of feed price may represent a substantial impact the financial margins of agribusiness and poultry farmers.

This means being essential terms excellent formulations to seek the best chicken performance, where the feed is the best possible. But only this is not enough, you need to treat food with care and provides it so that the absorption of nutrients provided in it are absorbed by the bird in its entirety.

Feed conversion in live weight is a complex process and the cause of a good or bad conversion rate typically involves several factors which can be classified into three fronts:

QUALITY OF FEED:

- Quality of ingredients used

- Manufacturing Processes

- physical form of feed (pellet quality)

- Power Programs

HEALTH:

- Lot Management

- Vaccination

- infection free environment

- Biosafety

- Illnesses

MANAGEMENT:

- Incubator

- Temperature

- Water management

- Management of feed

- Ventilation

.jpg)

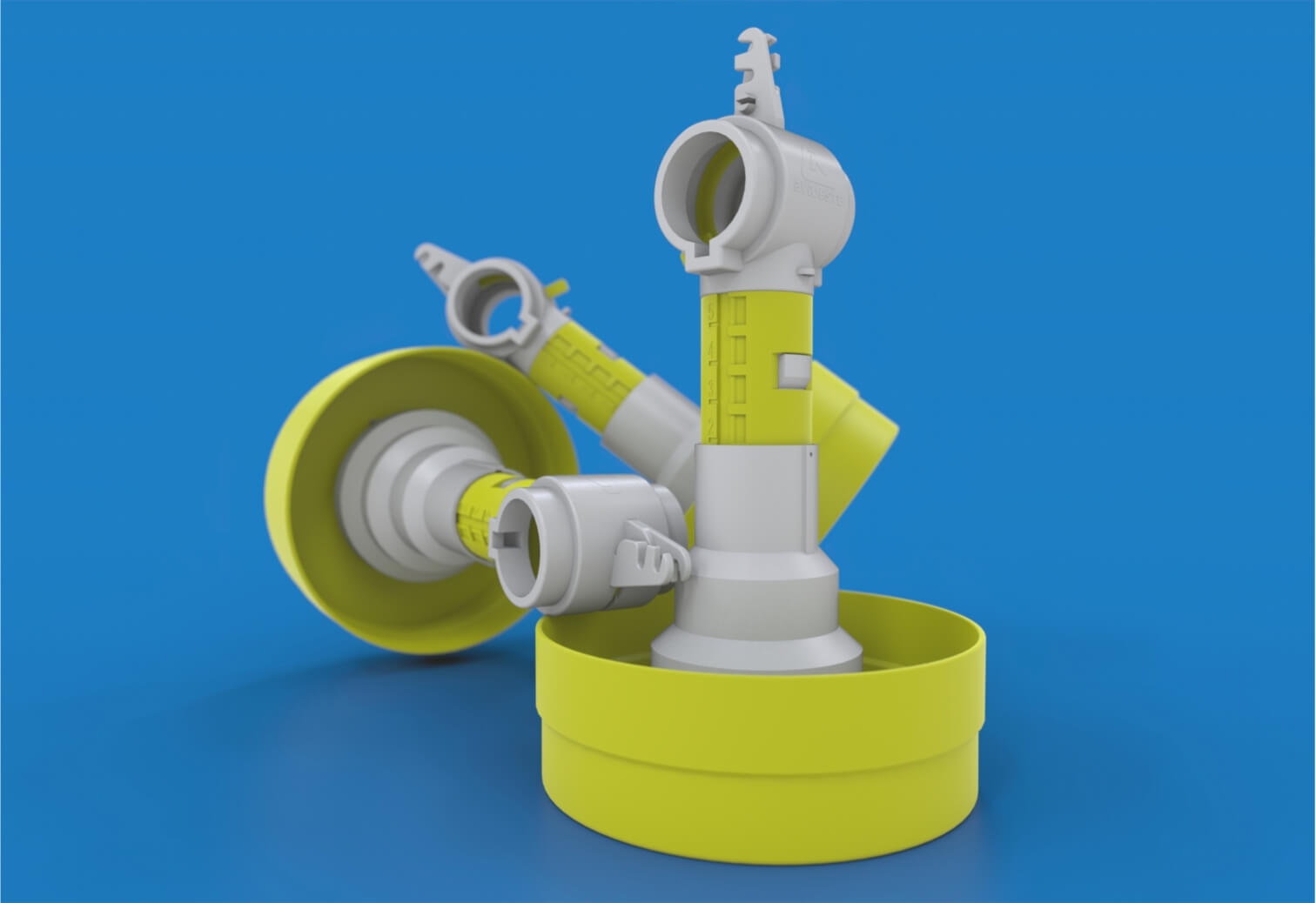

In this study bring information about the success in the management of feed using the automatic plate feeder Sintesi Avioeste .

During the transport and distribution of feed, can occur segregation of its constituents, especially if it is of low quality. This may result in the formation of fine particles in the trough base. If there is a lot of feed in a large conventionally course, there will be movement of this feed in the dish and a large segregation of fines will remain in the bottom of the dish, and this occurs less frequently in the plate feeder Synthesis, because it constantly providing smaller amounts of feed to each feed drive of the transport system (helicoide system).

The Sintesi original plate is made of high density and polypropylene with anti-UV protection; It has a single locking system which prevents decides to feed food that are not used in the initial phase; comprises adjustment of the distribution of feed collectively; It is easy to clean, regulation and management; frequent drives encourage feed consumption continuously; the little amount of food on the plate offers food always clean and new; besides of course be easily accessible to the chicks from day one and be easy to clean during batch interval.

Although most research on feeding behavior of birds have approached productivity levels and physiological responses of birds is very important to consider social characteristics involved in the poultry feed process.

It is technical knowledge that there are hierarchies in the social life of birds.

When birds are in flocks, as in the case of an aviary, the dominant birds will always have first access to the power supply (ie after the start of illuminance of the aviary, either through use of natural or artificial lighting). This occurring, the dominant birds can impair access to feeders for parts of other birds.

When used as a source of supply of feed large conventional feeder plates allow a large amount of feed available, and will tend birds to feed more slowly as they realize that the food is there exposed without any possibility of "up quickly". Psychologically this makes the dominant birds, which arrive first to the feeders, to feed more slowly and may even sit / lie down in front of the feeders while feeding, very damaging access to other birds to the feeders.

When using the plate feeder Sintesi to supply feed to the birds, due to lower availability "instant" feed the birds who first come to feeders tend to feed more quickly because they understand that there is a "shortage" of food and go away faster front of feeders, thus allowing other birds can reach easily to the feeders.

With automatic feeding system, will not lack of food supply, because the more the birds feed plus the feed transport system will deliver the fresh feed at the feeder plate, thus allowing all birds have easy access to a ration cool high quality.

There will be no problem to some in this new "rhythm" to feed the birds because the chicken feeds with greater or lesser amounts of food eaten in each trip to the feeder, as the greater or lesser availability of food. Assuming that the food must be eaten quickly the bird i eat ha larger amounts of food on each trip to the trough, thus allowing it to feed properly consuming the required amount you need for your good growth so getting good levels of feed conversion .

The waste feed in the poultry feed process is a factor that greatly affect a good feed conversion. To this does not occur the waste feeder plate Sintesi allows to work with specific settings for each stage of growth of the chicken providing good amounts of food and promoting better utilization of feed consumption.

Since its launch in the market for over ten years, the plate feeder Synthesis has proved satisfactory in the field, due to its easy handling, easy to maintain and provide excellent feed conversion values.

Not having partitions bars the plate feeder Sintesi allows easy access to birds, and reduce the impact of physical barriers that can hinder the access of birds to feeders, not occurring discomfort visual to the birds allowing that they can get a good picture of what happens around you even in moments that they are feeding on the plates.

.jpg)